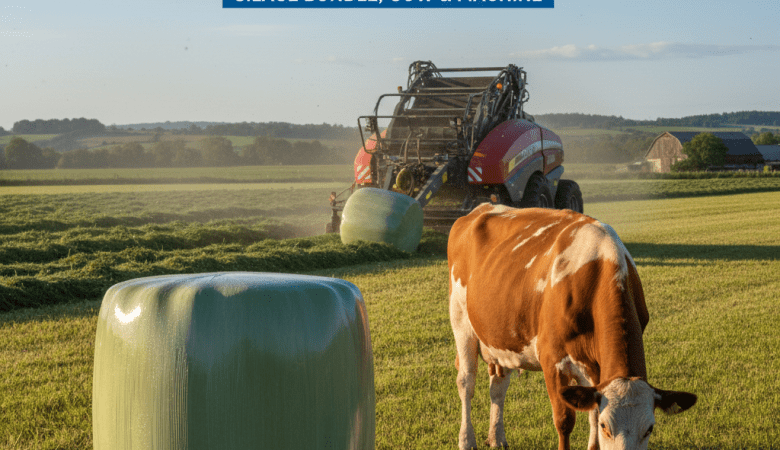

Silage Pit Construction for Small Farmers

Silage Pit Construction for Small Farmers: A Step-by-Step Low-Cost Guide Silage is an essential feed resource for dairy farmers, especially during dry seasons when green fodder is scarce. For small farmers, building a silage pit doesn’t need to be expensive or complicated. With some planning and basic materials, you can create an effective silage pit that preserves nutritious fodder for your cows and buffaloes. This guide provides a simple, step-by-step approach to constructing a low-cost silage pit suitable for small farms. Why Small Farmers Should Consider Silage Pits Green fodder tends to be seasonal, and during lean periods, animals may not get enough nutrition, affecting milk yield and overall health. Silage pits allow farmers to store excess fodder in a controlled environment, ensuring year-round feed availability. Some key benefits include: Cost savings: Reduce dependence on purchased fodder. Better nutrition: Well-made silage preserves vitamins and minerals in fodder. Improved milk production: Consistent, high-quality feed leads to higher milk yield. Reduced wastage: Proper storage prevents spoilage of green fodder. Step-by-Step Guide to Constructing a Low-Cost Silage Pit 1. Select the Right Location Choose a site that is: Slightly elevated to avoid waterlogging. Close to the feeding area for easy access. Away from areas prone to flooding or runoff. 2. Determine Pit Size The size of your silage pit depends on: The number of animals on your farm. The quantity of fodder you expect to harvest in a season. Rule of thumb: A pit width of 2–3 meters, length of 5–10 meters, and depth of 1.5–2 meters works well for small farms. 3. Prepare the Pit Base Clear the area of debris and vegetation. Dig a pit to the required depth. If possible, line the base with a layer of sand or gravel to improve drainage and prevent water accumulation. 4. Construct Pit Walls Use bricks, concrete, or stone to build low walls along the sides. For a very low-cost option, farmers can use compacted earth reinforced with bamboo or wooden planks. Ensure walls are firm enough to support the weight of fodder piled on top. 5. Fodder Preparation Harvest green fodder at its peak nutritional value. Chop fodder into 2–4 inch pieces to ensure proper compaction and fermentation. 6. Filling the Pit Layer the chopped fodder evenly in the pit. Compact each layer by treading or using a wooden pole to remove air pockets. A well-compacted pit reduces spoilage and ensures uniform fermentation. 7. Covering the Pit Cover the filled pit with a thick plastic sheet or tarpaulin to prevent air entry. Place a layer of soil or sand on top of the plastic to hold it down and prevent damage by wind or animals. 8. Fermentation Process Allow the fodder to ferment for 3–4 weeks. Check occasionally for leakage or damage to the covering. Avoid opening the pit prematurely to maintain proper fermentation. 9. Using the Silage Remove silage from the pit in small quantities as needed. Always take fodder from the top to maintain the integrity of the remaining silage. Feed to cows and buffaloes gradually to monitor their acceptance and milk response. Tips for Low-Cost Silage Pit Success Reuse materials: Old bricks, bamboo, or plastic sheets can reduce construction costs. Prevent water seepage: Proper drainage ensures silage doesn’t rot. Regular monitoring: Keep an eye on the pit during rainy seasons to avoid spoilage. Keep animals away: Fencing or barriers prevent silage contamination. Conclusion A DIY silage pit is an affordable and practical solution for small farmers to ensure year-round fodder availability. By following these simple steps, you can build a low-cost pit that preserves the nutritional quality of green fodder, reduces wastage, and boosts milk production. With proper care and management, even a small farm can reap the benefits of silage without significant investment. 1. What is the best size for a silage pit on a small dairy farm? The ideal silage pit for small dairy farms is about 2–3 meters wide, 5–10 meters long, and 1.5–2 meters deep, depending on the number of animals and daily feed requirements. 2. How can small farmers build a low-cost silage pit at home? Small farmers can build a silage pit cheaply by digging an earthen pit, lining it with plastic, compacting chopped fodder, and sealing it with soil or sand. 3. Which type of fodder is best for making silage? The best crops for silage include maize, sorghum, napier grass, and sugarcane tops, harvested at the right maturity for maximum nutrition. 4. How long does silage fermentation take in a pit? Silage typically ferments within 21 to 30 days, after which it becomes stable and ready for feeding dairy animals. 5. How can farmers prevent silage from spoiling in the pit? To avoid silage spoilage, ensure proper compaction, airtight covering, and water drainage. Always remove fodder from the top, not sides. 6. What materials are needed to construct a silage pit? You’ll need a shovel, plastic sheet, soil, bricks or bamboo (optional), and chopped fodder. Reusing old materials can further reduce costs. 7. How much silage can feed one cow per day? A dairy cow consumes about 25–30 kg of silage per day, depending on body weight and milk production levels. 8. Can silage be made without a pit? Yes, silage can also be made in silage bags, drums, or bunkers—ideal for farmers with limited space or needing portable feed storage. 9. What are the benefits of silage for milk production? Feeding silage helps boost milk yield, improves digestion, provides consistent nutrition, and reduces seasonal feeding stress on animals. 10. How long can silage last in a properly sealed pit? When properly fermented and sealed, silage can last up to 12 months without losing its nutritional quality. The ideal silage pit for small dairy farms is about 2–3 meters wide, 5–10 meters long, and 1.5–2 meters deep, depending on the number of animals and daily feed requirements. Small farmers can build a silage pit cheaply by digging an earthen pit, lining it with plastic, compacting chopped fodder, and sealing it